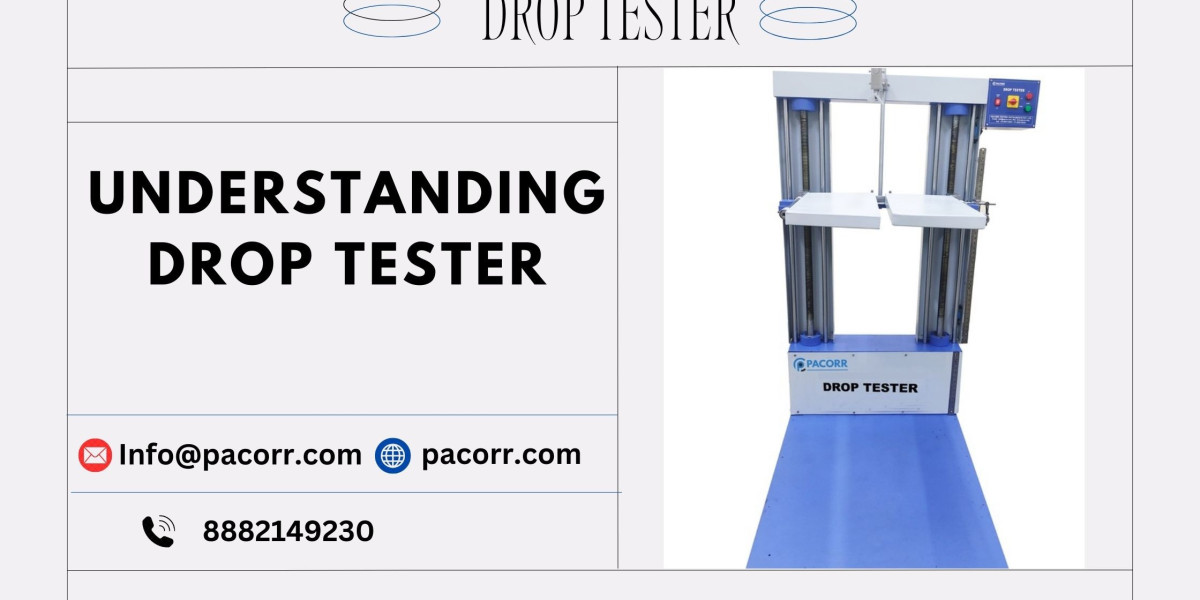

Drop Tester . It is designed to simulate real-world conditions where products experience falls during storage, handling, or transportation. In this article, we’ll take an in-depth look at the Drop Tester, its benefits, how it works, and why it is an essential tool for manufacturers.

What is a Drop Tester?

A Drop Tester is a piece of testing equipment used to evaluate how well a product can withstand impact forces caused by drops. It is commonly used to test the packaging materials, such as cardboard boxes, bottles, and cans, to ensure that they can endure rough handling during transit or storage. The test involves dropping a product from a specific height onto a hard surface and observing any potential damage. This test helps manufacturers ensure that their products and packaging can survive unexpected mishandling without compromising the safety or integrity of the items inside.

How Does the Drop Tester Work?

A Drop Tester typically consists of a platform, a mechanism to drop the product from a specified height, and a testing surface (usually a hard material like concrete or metal). The process of testing is relatively simple but highly effective in assessing a product's durability:

- Test Setup: The product or package is placed on the testing platform.

- Height Adjustment: The height from which the product will be dropped is adjusted according to the test specifications, which can vary depending on the product and industry standards.

- Release Mechanism: Once the test is set up, the product is dropped freely onto the hard surface. The fall simulates potential handling during shipment, such as a box falling from a warehouse shelf.

- Damage Assessment: After the product impacts the surface, the tester examines it for any physical damage, deformation, or functional failure.

Why is Drop Testing Important?

Drop Testing is crucial for several reasons. It helps manufacturers:

- Assess Packaging Durability: Products, especially fragile items like electronics or glass bottles, need packaging that can protect them during transit. The Drop Test simulates drops to ensure that packaging materials like boxes, shrink wrap, and pallets can withstand impact without damaging the contents.

- Minimize Product Returns: If a product is damaged during transportation, it can lead to costly returns and customer dissatisfaction. The Drop Test helps prevent these issues by ensuring that products and their packaging can endure the rough handling they might experience.

- Comply with Industry Standards: Many industries, including the pharmaceutical, electronics, and consumer goods sectors, have strict regulations regarding product durability. Drop testing allows manufacturers to meet these standards, ensuring their products are safe and fit for use.

- Improve Product Design: Through drop testing, manufacturers can identify weak points in product designs or packaging, leading to improvements that ensure better protection for customers and reduce the risk of damage.

Types of Drop Tests

Different products require different kinds of drop tests. Here are some common variations:

- Free-Fall Drop Test: This is the most basic form of Drop Tester Price , where the product is dropped from a specific height and allowed to fall freely onto a hard surface. It’s commonly used for packaging materials and products with relatively low fragility.

- Edge Drop Test: In this variation, the product is dropped on its edge, which is often the most vulnerable part of a package. This test is commonly used for products like cardboard boxes to see how well they hold up when dropped on a corner or side.

- Corner Drop Test: This test involves dropping the product at its corner, simulating a real-world scenario where the corner of a package bears the brunt of the impact. It is often used to test rigid packaging like cartons or boxes.

- Flat Drop Test: In this test, the product is dropped flat onto the testing surface, testing the overall structural integrity when it impacts a large surface area. This is especially useful for checking products that are placed in flat packaging.

Standards and Regulations for Drop Testing

There are several industry standards and guidelines that dictate how drop tests should be performed. Some of the most common include:

- ISTA (International Safe Transit Association): This organization sets out standards for packaging testing, including drop tests. Their ISTA 1A, 2A, and 3A tests specify different drop heights and methods depending on the type of product and packaging being tested.

- ASTM (American Society for Testing and Materials): ASTM has several standards related to drop testing, including ASTM D5276 for testing the impact resistance of plastic packages, and ASTM D3332, which applies to packaging of fragile goods.

- ISO (International Organization for Standardization): ISO standards like ISO 2248 and ISO 2874 set guidelines for packaging tests, including drop tests, ensuring that products can be shipped safely and without damage.

Benefits of Using a Drop Tester for Your Business

Investing in a Drop Tester offers numerous benefits for manufacturers:

- Quality Control: Regular drop testing helps maintain high-quality standards for your products, ensuring that customers receive goods in perfect condition, even after rough handling.

- Customer Satisfaction: By testing and improving the durability of your products and packaging, you reduce the likelihood of damage during transit, leading to better customer satisfaction and fewer returns.

- Cost-Effective: While drop testing involves initial investment in equipment and setup, it can save money in the long run by reducing product damage, minimizing returns, and avoiding potential lawsuits from defective packaging.

- Enhanced Brand Reputation: Brands known for reliable, well-protected products often enjoy better customer loyalty. With rigorous testing, you assure your customers that your products are trustworthy and well-packaged.

Choosing the Right Drop Tester for Your Needs

When selecting a Drop Tester, there are several factors to consider:

- Drop Height: Choose a tester that allows you to adjust the drop height according to the specifications of your products. Different products require different drop heights to replicate real-world conditions.

- Test Surface: The material of the surface on which the product lands is also critical. Harder surfaces like concrete may be more damaging, while softer materials like foam can provide a less aggressive test.

- Automation: Some advanced models offer automated drop mechanisms, allowing for multiple tests with little manual intervention. These testers provide consistency and precision in the results.

- Testing Modes: Depending on your testing needs, you might require a tester that supports different drop testing modes (e.g., free-fall, edge, corner, flat) to simulate various types of impacts.

Conclusion

The Drop Testing is an essential tool for testing the durability and reliability of products and packaging. By simulating the impact of falls during transit, it helps manufacturers improve product quality, reduce costs, and ensure that their products are safe for use. Whether you are testing cardboard boxes, bottles, or fragile electronics, using a Drop Tester is a proactive step toward improving product performance, customer satisfaction, and brand reputation. At pacorr.com, we provide state-of-the-art Drop Testers that meet international standards, ensuring that your products are ready for the challenges of the real world.

FAQ for Drop Tester

1. What is a Drop Tester used for?

A Drop Tester is used to assess the durability of products, especially packaging, by simulating drops or impacts that occur during handling, storage, or transportation.

2. How does a Drop Test work?

The product is dropped from a specified height onto a hard surface, and the resulting damage or lack thereof is analyzed to determine its durability.

3. Why is Drop Testing important?

Drop Testing ensures that products can withstand handling during transport and reduces the likelihood of product damage and customer returns.

4. What types of Drop Tests are there?

Common types include Free-Fall, Edge Drop, Corner Drop, and Flat Drop tests, each targeting different aspects of product durability.

5. What standards guide Drop Testing?

Common standards include those from ISTA, ASTM, and ISO, which outline specific guidelines for conducting drop tests based on the type of product and packaging.

6. Can a Drop Tester be customized for different products?

Yes, modern Drop Testers allow for customization in terms of drop height, test surface, and drop modes to accommodate a wide range of products.