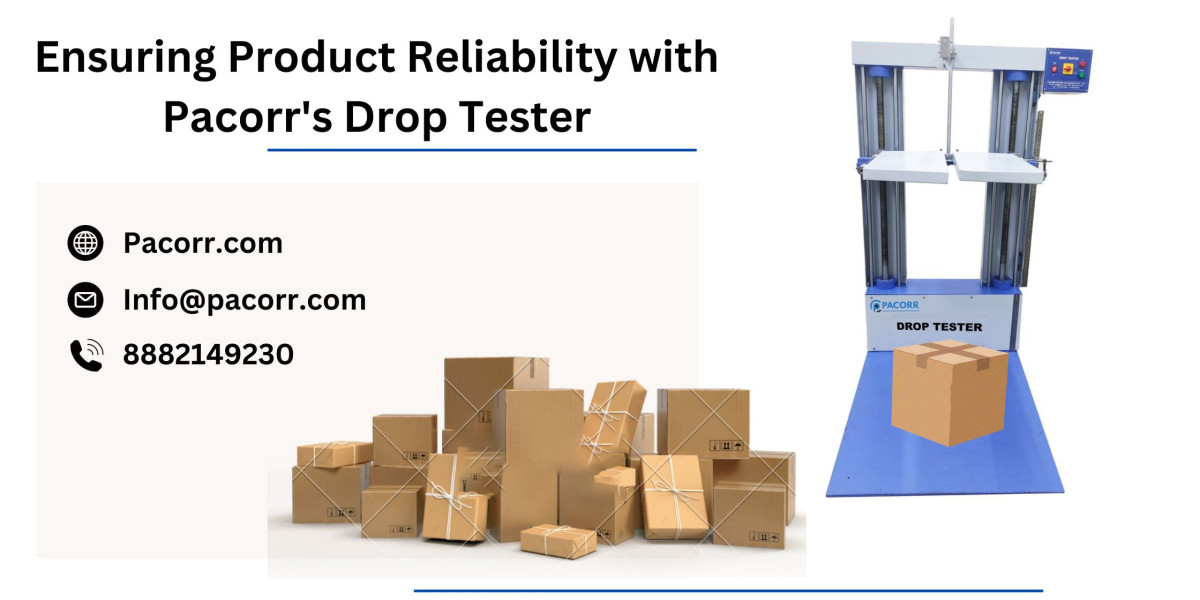

To minimize these risks and safeguard your products, Pacorr Testing Instruments Pvt Ltd offers the Drop Tester—a critical tool designed to evaluate the durability of packaging and ensure it can protect your products during transit.

What is a Drop Tester?

A Drop Tester is a device designed to simulate the drops and impacts that products often face during transportation. By dropping packaged products from controlled heights and measuring how well the packaging withstands the shock, the Drop Tester provides manufacturers with valuable data on whether their packaging design is effective in preventing damage to the product.

Why is Drop Testing Essential?

Shipping products means exposing them to a variety of potential hazards, from bumps and drops during loading to impacts during transit. Drop testing helps businesses assess their packaging’s ability to endure these challenges, ensuring that products arrive undamaged. Without proper testing, there’s a risk that packaging will fail when exposed to real-world conditions, leading to costly returns, replacements, and customer complaints.

Key reasons why drop testing is vital:

Prevents Product Damage: Identifies potential weaknesses in packaging before products are shipped out, ensuring they are well-protected.

Cost Savings: Prevents damage-related expenses such as returns, replacements, and repairs.

Packaging Improvement: Provides essential feedback that allows businesses to optimize packaging for better protection.

Features of Pacorr’s Drop Tester

The Drop Tester from Pacorr is designed with several key features that make it an ideal solution for testing packaging durability:

Adjustable Drop Heights: The tester allows you to modify the drop height, simulating different shipping conditions and ensuring that your packaging can handle varying levels of impact.

Compatibility with Various Materials: Whether it’s cardboard, plastic, glass, or other materials, the Drop Tester can accommodate a variety of packaging types, making it versatile for different industries.

Accurate and Repeatable Results: The device ensures consistent testing, providing reliable results that you can count on for making data-driven decisions.

User-Friendly Interface: The Drop Testing features an intuitive design that makes it easy to operate with minimal training, streamlining the testing process.

Durable Construction: Built to withstand regular use, the Drop Tester is made with high-quality materials to ensure it remains functional over time.

Applications of the Drop Tester

The Drop Tester is used across several industries where packaging protection is critical. Some of the key applications include:

Electronics: Sensitive electronics such as smartphones, laptops, and other gadgets require secure packaging to prevent damage during shipping. Drop testing ensures the packaging can withstand impacts.

Consumer Goods: Products like cosmetics, toys, and household appliances must be carefully packaged to prevent breakage during shipping. Drop testing ensures the packaging protects them effectively.

Food and Beverage: Packaging in the food industry must remain intact during transit to prevent contamination or spoilage. Drop testing guarantees the strength and durability of food packaging.

Pharmaceuticals: Medicines and medical devices require robust packaging to avoid damage during shipping, as even minor damage can compromise the product. Drop testing ensures the packaging protects these products.

Industrial Products: Industrial equipment and tools are often heavy and prone to damage during shipping. Drop testing ensures that the packaging is strong enough to withstand drops and rough handling.

Benefits of Using Pacorr’s Drop Tester

Prevents Damage: Drop testing ensures your products remain undamaged during shipping, protecting your investment and your brand reputation.

Optimizes Packaging Designs: By identifying flaws in packaging design, drop testing allows you to make the necessary adjustments to improve packaging strength and reliability.

Saves Money: By preventing packaging failures and product damage, businesses can save money on returns, replacements, and repair costs.

Boosts Customer Satisfaction: Packaging that ensures products arrive in excellent condition leads to higher customer satisfaction, fewer complaints, and greater trust in your brand.

Meets Industry Standards: Drop testing helps you ensure your packaging meets the necessary industry standards for product protection, allowing you to comply with regulations.

Why Choose Pacorr’s Drop Tester?

The Drop Tester Price from Pacorr is an essential tool for any business looking to ensure its packaging can withstand the challenges of shipping. With its ability to simulate real-world conditions, adjustable settings, and reliable results, the Drop Tester is the ideal solution for testing packaging durability. By using this tool, businesses can improve packaging designs, reduce damage-related costs, and ensure their products are well-protected during transit.